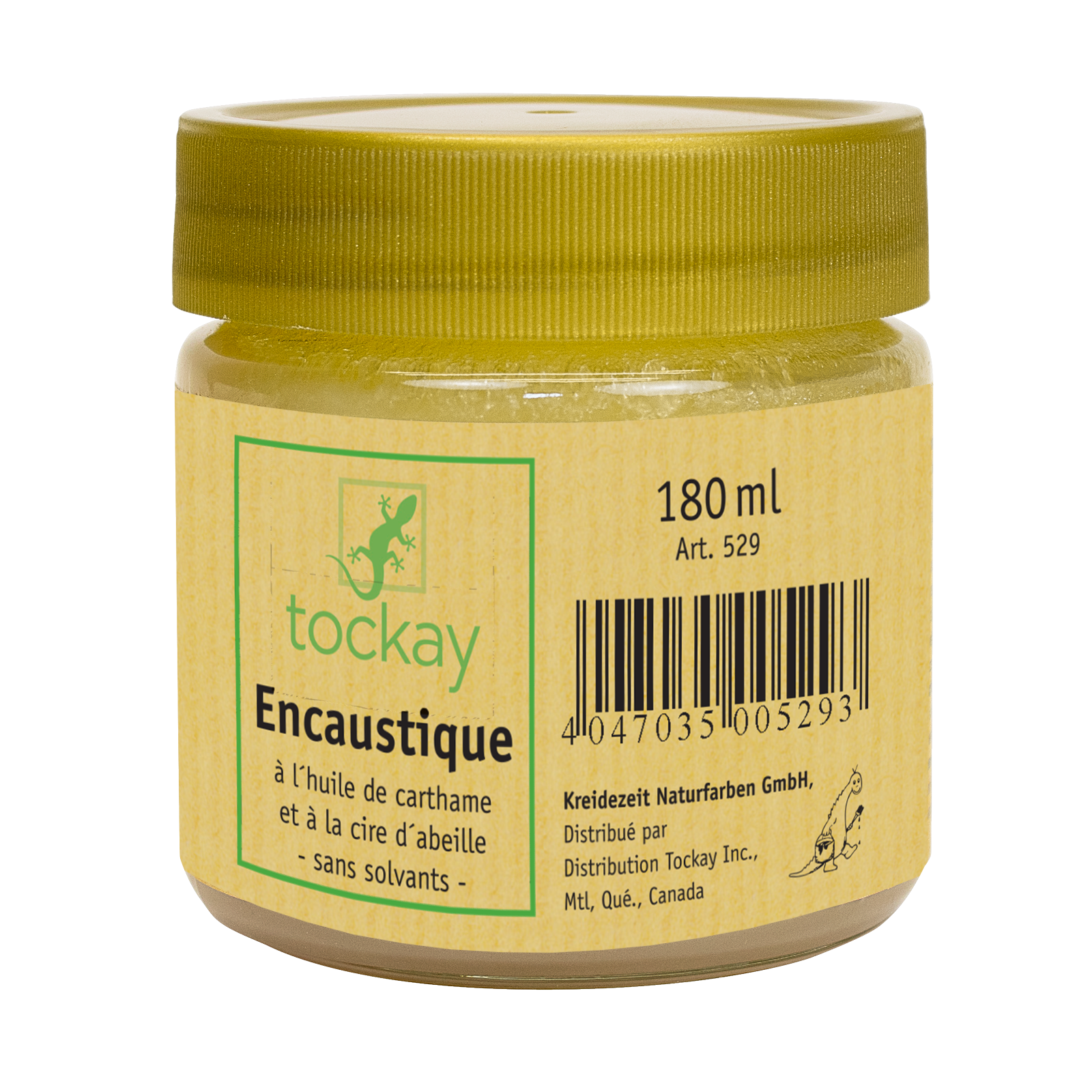

Safflower Wax Encaustic

$21.00

The encaustic with safflower oil and beeswax is particularly recommended for the protection of raw wood like furniture or surfaces made of Tadelakt.

WINTER DELIVERY: Due to the sensitivity of our liquid products to freezing temperatures, please contact us before placing an order if the delivery is outside the Greater Montreal area.

| Format | Consumption | CAD $ |

|---|---|---|

| 180 ml | Approx. 60 ft² | 21.00 |

In stock

Description

The encaustic with safflower oil and beeswax is particularly recommended for the protection of raw wood like furniture or a surface made of Tadelakt. It is composed of a mixture of purified beeswax, safflower oil and clarified wood oil. The colors of surfaces treated with encaustic remain beautiful and undergo almost no yellowing, unlike the treatment with products containing linseed oil.

Application

When using the product, the complete product information must be observed.

TOOLS

– Lint-free cloth, solvent-resistant synthetic sponge

– Brush / flat brush

PRELIMINARY TEST

It is recommended that a test application be made on an inconspicuous part of the surface to evaluate the colour change of the substrate and to check for other possible reactions.

SUITABLE SURFACE

The substrate must be untreated, clean, dry, grease-free, chemically neutral and absorbent. Apply the oil at a minimum temperature of 10 °C. The moisture content of the wood must be < 15%. Do not use on damp wood!

APPLICATION

Mix the product well before use. Remove all oxidation layers caused during storage.

Apply one or two coats, allowing drying time between coats. Depending on the surface, sanding may be necessary before applying the second coat.

If using multiple jars with different lot numbers, mix them together before application.

Do not pour the polish directly on the substrate.

Clean and dust untreated surfaces.

To ensure good penetration of the encaustic on dense, low absorbency, tannin-rich wood such as oak or chestnut, it is recommended to dilute the encaustic with at least 20% balsamic turpentine for the first coat.

1- Initial sanding:

Sand the wood (80-100 grain), round the edges and remove dust. Do not use finer sandpaper to avoid densifying the wood and limiting its capacity to absorb oil. New, smooth, planed or finely pre-sanded wood should be coarsely sanded to ensure oil absorption. Dust carefully after sanding.

2- First coat:

Apply the product evenly with a brush, a cloth, or a sponge. Wait 10 to 20 minutes before rubbing carefully with a lint-free cloth until a uniform satin finish is obtained.

While polishing, remove any excess that could lead to poor drying or a sticky surface. Tockay safflower oil and beeswax polish must fully penetrate the wood, it must not form a film on the wood.

3- Sanding between coats (optional):

Intermediate sanding between the two coats is necessary when the wood fibers rise after the application of the first coat. Sand in the direction of the wood fibers (100-120 grain), then remove dust.

4- Second coat:

A second coat may be necessary on more absorbent surfaces. Proceed as for the first coat.

5- Wax treatment:

To accentuate the shine, use Carnauba wax floor milk. It is applied after a minimum of 48 hours of drying: dilute 1 volume of floor milk with 2 volumes of water. Apply evenly and thinly, then let dry and polish as needed.

TIPS FOR LARGE SURFACE APPLICATIONS

The application of encaustic on large surfaces such as siding or beams can be difficult due to the need to wipe off excess on rough wood. In this case, it is recommended to dilute the polish with balsamic turpentine in a 1:1 ratio.

Apply this mixture in thin and regular layers with a soft brush. Let dry without polishing. Once the encaustic has dried, polish all frequently touched areas with a horsehair brush until they become glossy.

TINT

Encaustic can be tinted with any Tockay pigment. Mix the pigments in a small amount of oil until a lump-free paste is formed, then add it to the main mixture. Pigments can be mixed with each other. Alternatively, encaustic can be tinted with oil paint in any ratio.

DILUTION

The encaustic can be diluted with balsamic turpentine.

DRYING

Dries and can be recoated after approximately 24 hours at 20°C and a humidity level of approximately 60% (48 hours for woods with high tannin content such as oak or chestnut). Cold temperatures, higher humidity and tannin-rich woods can significantly extend the drying time. Protect the treated surface from water until the final hardness is reached (about 4 weeks).

MAINTENANCE

The surface must be treated again as soon as it becomes absorbent again, and in any case, as soon as gray spots start to appear. The level of absorption can be assessed by wiping the surface wet. If the surface becomes darker, applying a new coat is necessary. To do this, reapply the product using the same procedure as above. Very stubborn dirt can be removed beforehand with a scouring pad, an abrasive cloth or sandpaper (100 grain).

CLEANING AND MAINTENANCE

– Protect the treated surface from water for the first 4 weeks after application

– Dust with a soft cloth or a vacuum cleaner equipped with a raised floor brush

– Never wipe with hot water; use lukewarm water only

– Clean only with a slightly damp cloth

– Use only a soft cotton cloth

– Do not use microfiber cloths because they remove oil

– Wipe up spills immediately, do not let them dry before taking action

– To maintain/restore the shine, use Carnauba wax floor milk in the cleaning solution

– Only if necessary, clean with olive soap; use sparingly

CLEANING OF TOOLS

Clean immediately after use with balsamic turpentine, then with Marseille soap.

Technical Data

It should be noted that the yield may vary depending on the substrate, the application method and the quality of the surface. Determine exact consumption by testing.

Before using this product, consult its Technical Data Sheet

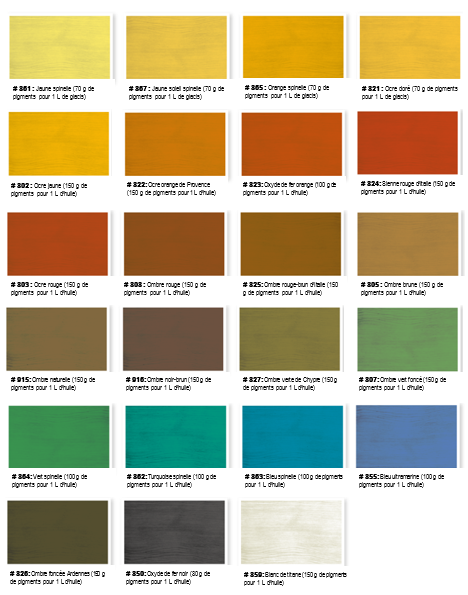

Colour Chart

Choose one of the 22 teints from our colour chart and rediscover the forgotten gestures of the artisan by mixing your own colour using Tockay’s natural dry pigments!

All natural, non-toxic, and free of petroleum-based components, our pigments are packaged in powder form and easily mixable to be incorporated into paint or plaster according to a precise recipe.

- Always make sure to eliminate lumps

- Only Ultramarine pigments should be used within 12 hours of preparation when mixed with a lime-based product

All color charts available online as well as paper brochures are for reference purposes only. Differences in shade representation may occur due to computer screen settings or printing.

The online colour guides are provided for information purposes only. Please note that colour tones may not always be displayed correctly by different monitors and their settings. The same applies to prints of these colour charts that you make yourself.

To get the best impression of our colours, we recommend the purchase of handmade colour charts made from casein paint and natural dry pigments.

To consult:

Colour chart of 22 colours and recipes for oils and waxes

Related products

-

Carnauba Wax Emulsion

$20.50 Select options This product has multiple variants. The options may be chosen on the product page -

Hard Oil – Pure Solid (solvent-free)

$49.50 – $132.00 Select options This product has multiple variants. The options may be chosen on the product page -

Auro White Gloss Paint

$46.50 Select options This product has multiple variants. The options may be chosen on the product page -

GekkkoSOL Lazure

$38.00 – $170.00 Select options This product has multiple variants. The options may be chosen on the product page