Description

Tockay 0.5 mm lime plaster is a natural coating for the interior. It is ideal for humid rooms such as bathrooms and kitchens because of its high alkalinity which makes it naturally antifungal. It is a powder product that can be diluted with water and applied with various spatulas. It can be tinted with the full range of Tockay natural dry pigments. It has an improved adhesion and is easy to apply and structure.

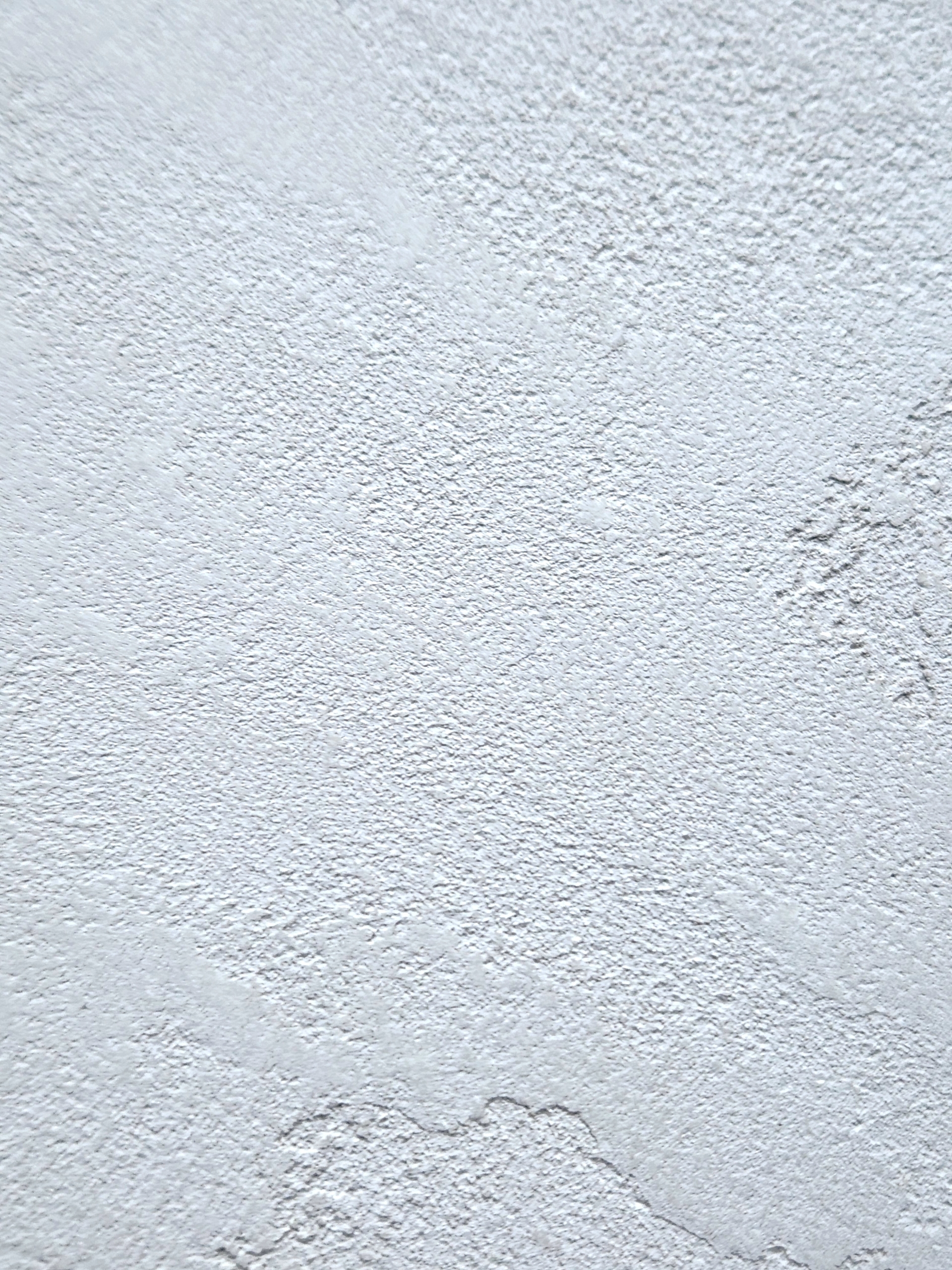

A variety of decorative effects are possible depending on the application technique chosen: textured in a rustic manner, plastered, or glossed with a spatula to create sumptuous fresco effects. The lime plaster can then be finished with Marseille soap, wax or glaze.