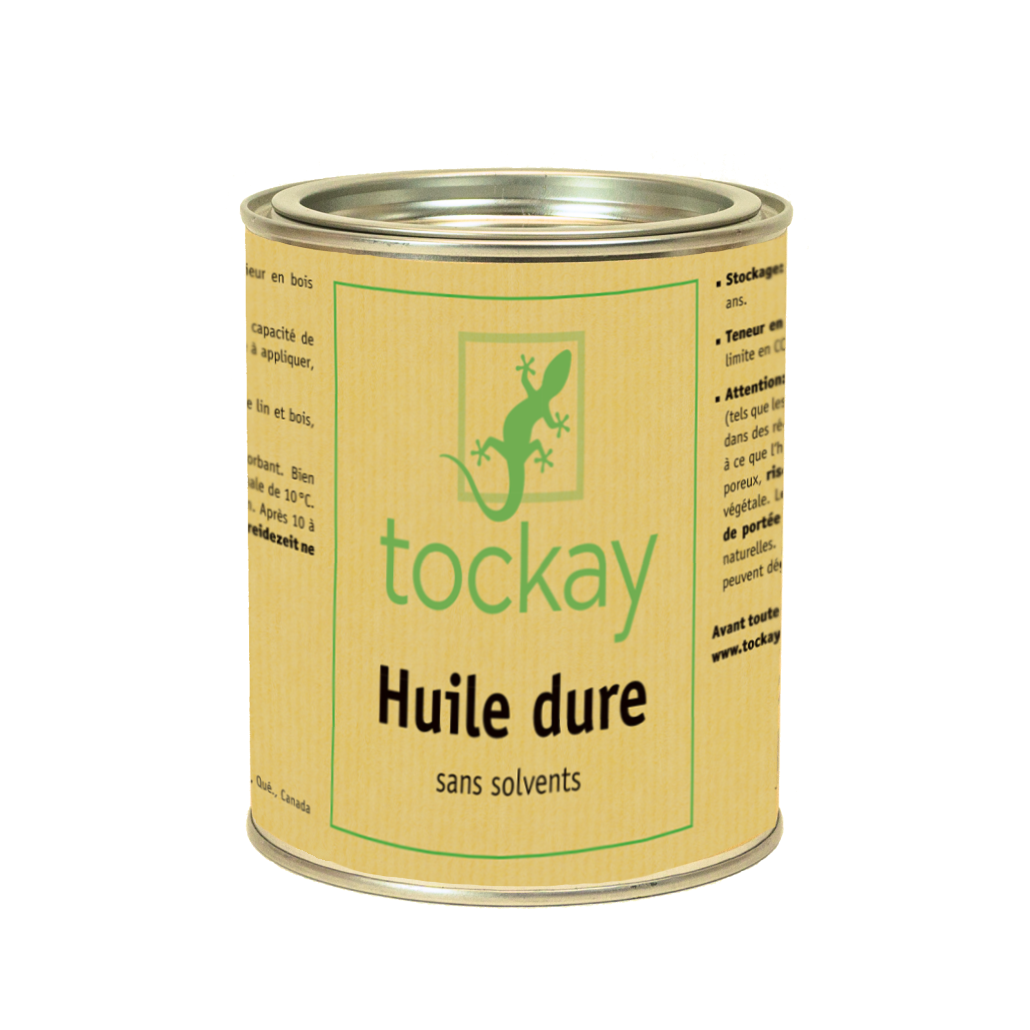

Description

Tockay solvent-free Hard Oil -Pure Solid- is used for interior wood such as floors, furniture, mouldings, doors, frames, toys, or countertops. It is also suitable for other surfaces such as cork, stone or terra-cotta and concrete in interiors. It is exclusively composed of natural oils and resins. It is applied with a flat brush, roller, or cloth. One to two coats are necessary depending on the quality of the surface, its absorbtion and the application.